INDUSTRIES

We Serve

Aerospace

Pharma

Automotive

Medical

Defence

Energy

INDUSTRIES

We Serve

Aerospace

Pharma

Automotive

Medical

Defence

Energy

Our Products

-

Test Chamber

- Growth Chamber

- Fermenter

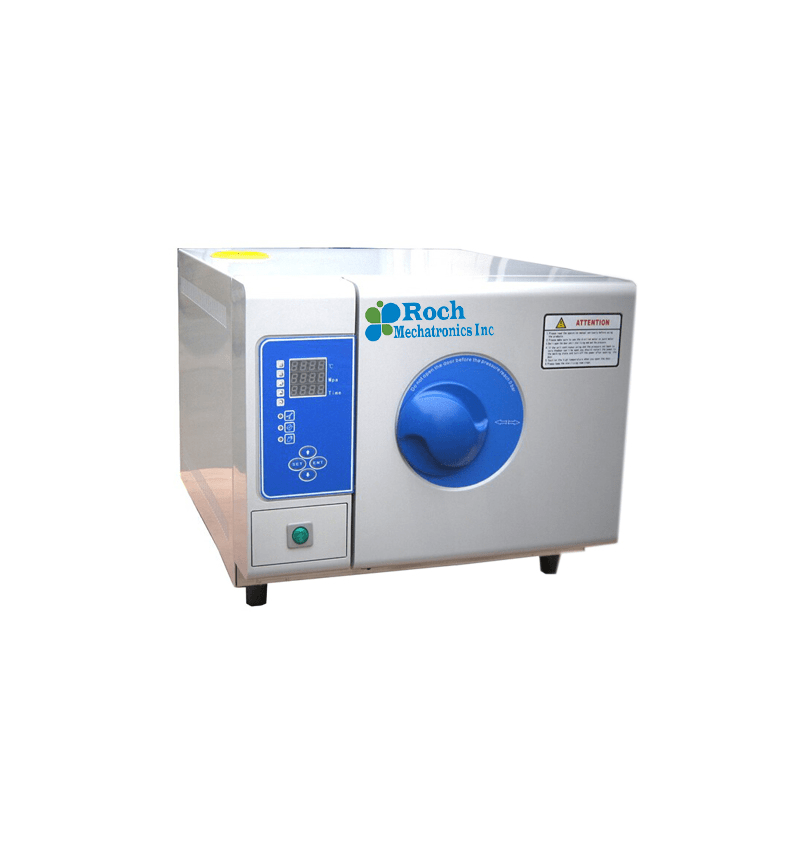

- Autoclaves

- Deep Freezer

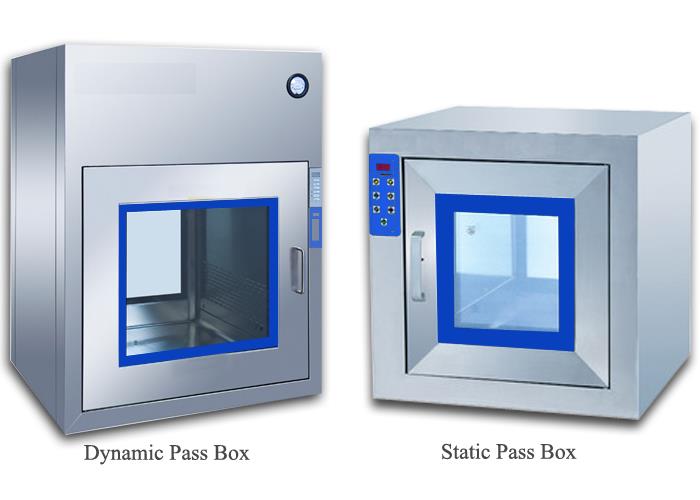

- Clean Room Equipment

Welcome To

ROCH Mechatronics Inc.

Roch Mechatronics Inc. is a reputed manufacturer of Laboratory equipment, lab equipments, and scientific equipment. We are an exporter of a wide range of laboratory equipment which includes incubators, Oven, autoclaves, electrophoresis, shakers etc to all over the globe. Our high-quality scientific equipment such as an autoclave is widely used for various research and experiments in schools, colleges, universities, and institutes.

We in order to manufacture precise laboratory equipment have also installed various specialized machines like autoclaves that can easily manufacture products as per the provided specifications. Premium in quality and widely demanded our lab equipment is competitive in price and guarantees a long working life. Our scientific equipment like incubators, Ovens, autoclaves, electrophoresis, shakers, etc. are easy to use and also completely safe and have CE and GMP.

One – Stop Solution provider in Environmental testing

We have over 20 years experience in this industry.

Client’s Satisfaction

Value

Cost reduction by Value Engineering/ other methods, Wastage reduction

Sustainable Goal

Achieving and sustaining superior levels of performance in all operations

Services

Timely and effective customer support & services

Roch Mechatronics Inc…

Our Clients